CoreXY Belt-Driven Gantry System – Fast, Precise, and Space-Efficient 📩 contactus@imakerstore.com -To Get a Quote

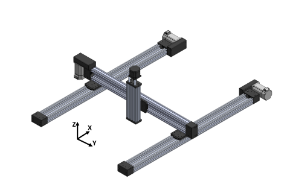

Our CoreXY/H-Bot belt-driven gantry is designed for applications that demand high-speed performance, precision positioning, and efficient use of space . Unlike traditional Cartesian setups, the CoreXY architecture allows lighter moving components , resulting in faster acceleration and higher travel speeds without compromising accuracy.

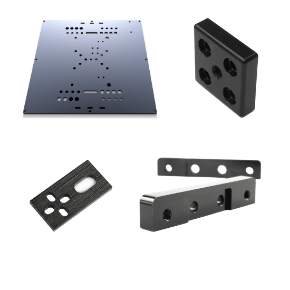

Built with precision timing belts , a rigid aluminum frame , and customizable working areas , this gantry is ideal for industrial, prototyping, and creative automation projects .

VIDEO

Key Features CoreXY Motion Architecture – Faster acceleration and reduced moving mass for higher efficiency.

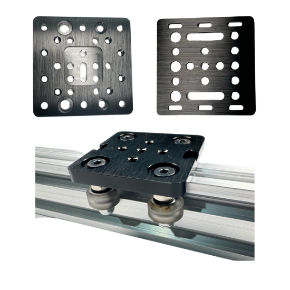

High Speed & Repeatability – Smooth, precise motion for demanding applications.

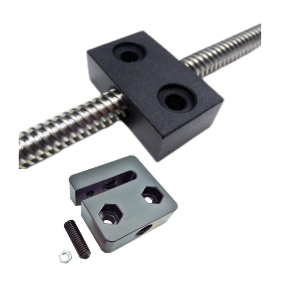

Reliable Belt Drive System – Minimal maintenance with consistent performance.

Customizable Size – Options available up to 1000×1000 mm and beyond.

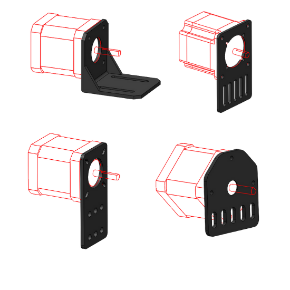

Motor Configurations – Supplied with NEMA 17 or NEMA 23 stepper motors depending on application size and load.

Cable Management – Integrated drag chain ensures tidy, protected cable routing.

Durable & Rigid Frame – Ensures stable operation even at high speeds.

Applications Pick-and-Place Automation – Fast and accurate material handling.

CNC Machining & Engraving – Precision cutting and engraving operations.

Laser Cutting & Engraving – Smooth, stable beam positioning.

3D Printing – Ideal for high-speed, large-format printers.

Drawing & Plotting Robots – Consistent motion for technical or artistic outputs.

Inspection & Scanning Systems – Stable movement for vision-based quality checks.

Benefits Higher Productivity – Achieve faster cycle times without losing accuracy.

Compact Motion Design – Saves space while offering large working areas.

Flexible Integration – Works with various controllers, sensors, and end-effectors.

Custom Solutions Available – Tailored to your specific application requirements.

📩 For orders, technical details, and customization options: contactus@imakerstore.com

Here’s a clear comparison table between a CoreXY Belt-Driven Gantry and a Cartesian (XY) Belt-Driven Gantry that you can use in your catalog, website, or sales brochure:

Comparison table between a CoreXY Belt-Driven Gantry and a Cartesian (XY) Belt-Driven Gantry:

Feature CoreXY Belt-Driven Gantry Cartesian (XY) Belt-Driven Gantry Motion Architecture Belts arranged in a crossed configuration; both motors contribute to X & Y movement Independent X and Y axes; each motor drives a single axis Speed & Acceleration Higher acceleration due to reduced moving mass Slightly lower acceleration as the entire X-axis assembly moves for Y travel Precision & Repeatability Excellent, but requires careful belt tensioning for accuracy Excellent; simpler belt routing makes it easier to maintain precision Mechanical Complexity More complex belt arrangement and frame setup Simpler design, easier to assemble and service Frame Size vs. Work Area More space-efficient for the same working area Requires slightly larger frame footprint for same work area Maintenance Belt tension and alignment require more attention Easier to maintain due to simpler mechanics Best For High-speed applications, large-format 3D printing, laser engraving, fast pick-and-place systems CNC applications, medium-speed pick-and-place, drawing robots, inspection gantries Motor Configuration Two stationary motors (NEMA 17/23) drive both X and Y axes together One motor per axis (NEMA 17/23), moving mass is higher on Y axis Cost Slightly higher due to complexity and extra pulleys Generally lower due to simpler construction Working Area Options Easily scalable while maintaining high speed Scalable, but increased size may reduce acceleration performance

Refer to this link for kinematics: https://www.buildlog.net/blog/2017/10/the-midtbot-a-new-flavor-of-h-bot/

.png)